|

BEYOND DESIGN

I N C O R P O R A T E D |

||

Alligators |

||

|

|

|

The Alligator Project |

||

Alligators

Artists |

| Kelly |

| Nests |

| Rostovsky |

| Statue of Job |

| Alligators |

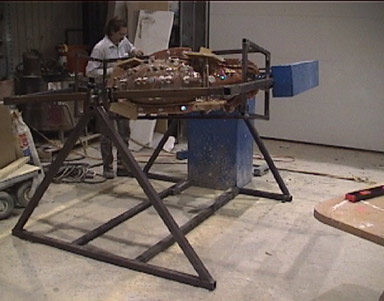

The alligators were created for a gallery in Florida and were used as a fund raiser. The original art was provided by the gallery and site molds were created by another company. Beyond Design produced the production molds, the production line and the final products.

For more about Rotocasting & What we can do with it